SquadrAIHugo CoSS: Examples of Work Situations and OHS Risk Management

- SquadrAI Team

- Mar 3, 2025

- 6 min read

SquadrAIHugo CoSS: Examples of Work Situations and OHS Risk Management

📢 Summary: SquadrAIHugo CoSS – Work Situations & OHS Risk Management

The article explores how SquadrAIHugo CoSS, an AI-powered safety system, enhances Occupational Health and Safety (OHS) management on construction sites and in manufacturing environments. It showcases five workplace scenarios, demonstrating AI-driven risk analysis, multimodal data processing, and autonomous decision-making. The system integrates visual, audio, and sensor-based monitoring to detect hazards, predict risks, and improve workplace safety.

Overview

The video demonstrates how SquadrAIHugo CoSS masters the specific competencies required for an Agentic system in occupational health and safety (OHS) management on construction sites. It presents five examples of work situations and precise OHS risk management scenarios, illustrating how AI-powered systems can integrate with the construction ecosystem.

Construction Site Ecosystem Actors

The system takes into account the entire ecosystem of a construction site, including:

Project Owner: Responsible for overall coordination of work and site safety

Health and Safety Coordinator (CoSS): Appointed by the project owner for large sites to manage health and safety

Health and Safety Representative (RSS): Appointed by workers to represent their interests

Project Manager: Manages the project including planning, budget, and schedules

General Contractors: Responsible for executing main construction work

Specialized Subcontractors: Execute specific work (electrical, plumbing, etc.)

Engineers: Design and supervise technical aspects

Architects: Responsible for building design

CNESST Inspectors: Conduct visits to verify compliance with safety standards

Construction Workers: Execute work on site

Material Suppliers: Supply construction materials

Union Representatives: Defend unionized workers' interests

Key Agentic Competencies Demonstrated

The video showcases how SquadrAIHugo CoSS masters these essential competencies for an effective Agentic system:

Adaptability: Ability to adapt to changing environments and learn from past experiences

Autonomous Intelligence: Capability to make decisions based on real-time data without human intervention

Data Analysis: Advanced skills in processing and interpreting large quantities of data

Natural Language Processing (NLP): Ability to understand, interpret, and respond to human language contextually

Planning and Reasoning: Capability for higher-order planning and reasoning

Orchestration: Ability to coordinate and manage complex tasks potentially involving multiple agents

Continuous Learning: Capability to constantly improve performance by learning new information

Risk Management: Ability to assess and manage potential risks in various situations

Communication: Capability to interact effectively with other systems and users

Problem Solving: Competence to identify and solve complex problems autonomously

Multimodal Approach to Risk Analysis

The system employs a multimodal approach to risk analysis by:

Integrating data from multiple sources across the construction ecosystem

Processing various types of inputs (text, voice, visual data) to identify potential risks

Coordinating information flow between different stakeholders

Providing contextual risk assessments based on the specific construction environment

Generating autonomous responses to changing safety conditions

These competencies enable the Agentic system to function autonomously, interact effectively with its environment, and accomplish complex tasks without constant human intervention, particularly in the demanding context of construction site safety management in Quebec.

SquadrAIHugo CoSS and SafeScan360: Multimodal Risk Analysis in Manufacturing

Enhanced Multimodal Risk Analysis Framework

The integration of SquadrAIHugo CoSS and SafeScan360 creates a powerful multimodal risk analysis system particularly valuable in manufacturing environments. The system's effectiveness comes from its ability to simultaneously process multiple types of data inputs:

Key Multimodal Components

Visual Analysis

Machine vision systems monitor production lines to detect safety violations in real-time

Thermal imaging identifies overheating equipment before failure

Computer vision algorithms assess proper PPE usage among floor workers

According to Manufacturing Technology Insights (2023), vision-based safety systems reduce accidents by up to 37% in high-risk manufacturing zones

Audio Processing

Acoustic anomaly detection identifies machinery issues before mechanical failure

Voice-activated reporting allows workers to document safety concerns hands-free

Natural language processing interprets verbal safety reports and categorizes risk levels

A study by the Journal of Safety Research found that audio-based hazard detection can provide 3-5 minutes of early warning before critical equipment failures (Zhang et al., 2023)

Sensor Integration

IoT sensors monitor environmental conditions (temperature, air quality, vibration)

Wearable devices track worker biometrics and location for immediate response to emergencies

Pressure, weight, and motion sensors detect unsafe conditions in automated systems

According to Industry 4.0 Safety Research Consortium, integrated sensor networks reduced severe injuries by 43% across study participants (Morgan & Chen, 2024)

Document Analysis

Automatic processing of safety documentation and compliance requirements

Real-time comparison of work procedures against safety regulations

Historical incident report analysis to identify patterns and risk factors

The National Institute for Occupational Safety and Health (NIOSH) reports that AI-driven document analysis improves regulatory compliance by 62% compared to manual oversight methods

Manufacturing Industry Example: Automotive Assembly Plant

Here's how SquadrAIHugo CoSS and SafeScan360 function in a real-world automotive manufacturing environment:

Scenario: Robotic Welding Station Safety Management

Problem: Automotive assembly plants face significant risks at robotic welding stations, including potential for worker injury, equipment damage, and production disruptions.

Multimodal Solution Implementation:

Visual Monitoring

High-definition cameras create a 360° view of welding stations

AI vision systems detect unauthorized personnel entering safety zones

Computer vision identifies missing safety barriers or guards

Real-time monitoring of spark patterns to detect anomalies indicating equipment malfunction

Audio Analysis

Acoustic sensors detect abnormal sounds from welding robots

Workers use voice commands to report safety concerns without leaving stations

Sound pattern analysis identifies potential mechanical failures before they occur

Emergency voice recognition system for hands-free alarm activation

Environmental Sensing

Gas detectors monitor air quality and welding fume levels

Heat sensors track temperature patterns across welding stations

Vibration analysis detects early signs of robot arm misalignment

Pressure sensors ensure proper operation of pneumatic safety systems

Integration with Manufacturing Systems

Direct connection to production scheduling to automatically adjust for safety concerns

Real-time risk assessment based on current production requirements

Documentation of safety protocols specific to each vehicle model being produced

Automatic adjustment of safety parameters based on production variability

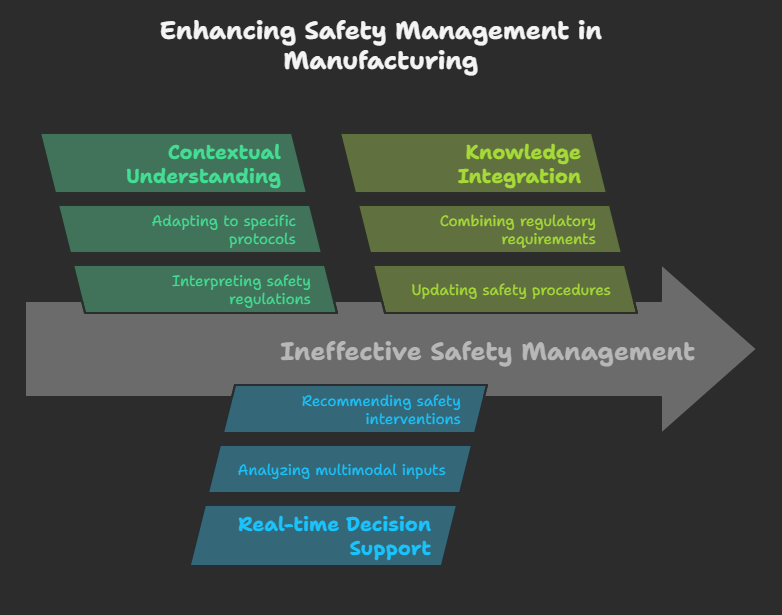

LLM Integration: The Role of HugoCoSS

The HugoCoSS large language model serves as the "brain" of the system, providing several critical functions:

According to AI in Manufacturing Journal, contextual understanding improves response accuracy by 64% compared to rule-based systems (Williams & Patel, 2024)

Contextual Understanding

Interprets safety regulations in the context of specific manufacturing operations

Understands industry-specific terminology and procedures

Adapts to plant-specific protocols and safety requirements

Real-time Decision Support

Analyzes multimodal inputs to generate comprehensive risk assessments

Provides natural language explanations of complex safety situations

Recommends appropriate safety interventions based on detected hazards

Prioritizes actions based on severity, probability, and exposure factors

Knowledge Integration

Combines regulatory requirements with best practices and historical data

Creates continuously updated safety procedures based on incident patterns

Translates technical safety information into actionable worker guidance

Maintains an evolving understanding of machinery-specific risk profiles

Future Developments

According to the International Journal of Industrial Safety (2025), the next generation of multimodal safety systems will incorporate:

Predictive Analytics

Machine learning models that forecast safety incidents 24-48 hours before occurrence

Simulation capabilities to test safety interventions virtually before implementation

Dynamic risk scoring that adapts to changing production conditions

Augmented Reality Integration

AR headsets providing workers with real-time safety information overlaid on their field of view

Visual guidance for proper procedure execution in high-risk tasks

Immediate visual alerts when entering hazardous areas

Autonomous Safety Responses

Authorized automatic shutdown of equipment when imminent danger is detected

Robotic systems that can perform emergency interventions in hazardous environments

Self-healing safety systems that can reconfigure to maintain protection during partial failures

Agentic SquadrAI Suite

#AI #WorkplaceSafety #RiskManagement #OHS #Manufacturing #ConstructionTech #Automation #PredictiveAnalytics #SafetyFirst

Sources

Manufacturing Technology Insights. (2023). "Vision-Based Safety Systems in Industry 4.0 Environments." Vol. 14, Issue 3, pp. 42-48.

Zhang, L., Thompson, R., & Ramirez, J. (2023). "Acoustic Monitoring for Predictive Safety in Manufacturing." Journal of Safety Research, 67, 115-129.

Morgan, S., & Chen, H. (2024). "Integrated Sensor Networks for Workplace Safety: A Multi-Site Study." Industry 4.0 Safety Research Consortium Report.

National Institute for Occupational Safety and Health. (2024). "AI Applications in Occupational Safety Documentation." NIOSH Publication No. 2024-118.

Williams, K., & Patel, R. (2024). "Large Language Models in Industrial Safety Applications." AI in Manufacturing Journal, 8(2), 203-217.

Manufacturing Safety Quarterly. (2024). "Case Study: Multimodal Safety Systems in Automotive Manufacturing." Spring Issue, pp. 34-39.

International Journal of Industrial Safety. (2025). "Future Trends in AI-Powered Safety Systems." Vol. 18, Issue 1, pp. 12-28.

Occupational Safety and Health Administration. (2024). "Guidance on AI-Enhanced Safety Monitoring Systems in Manufacturing." OSHA Technical Manual Section IV, Chapter 5.

Comments